But, I want to repeat my three basic guidelines:

1. You get what you pay for.

2. It doesn't have to be called interfacing to be interfacing.

3. For success - all fabrics (inside and out) have to be pre-shrunk ... even fusibles

So how do you pre-shrink a fusible?? just wet it and hang it up to dry like this ...

So, trying to actually be helpful to everyone, I've explored what information is available on line and found a couple very useful discussions. This one at The Savvy Sewer gives lots of good advice particularly about fusible interfacing. And this interview at Gertie's New Blog for Better Sewing is with a woman pushing her brand of fusible interfacing, but it sounds like good interfacing. I should give it a try. As I said above ... I do believe you get what you pay for.

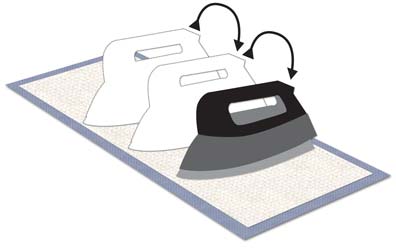

When I use a fusible nine times out of ten I use it on an facing, so if it does bubble no one will know. Also, if I am going to use a fusible I tend to use it on smaller pieces. The riskier or most challenging place to use a fusible is on a large piece, like the front of a tailored jacket or bodice of a very fitted gown. It is just so tricky to get the iron to the correct temperature and to move a home iron from section to section so that it fuses equally. I imagine some people are able to do this. The advice, of course, is test, test, test. And I know the correct iron technique is to move the iron like this ...

Interlining is just another name for flat lining which is just sewing a second layer of fabric along with your main fabric as if they were one like this ...

REALLY, if you want to use fusible interfacing, check out the two links I've provided above. They give you the tips and advice that should help you have success.

Next interfacing installment I will talk about all the different fabrics that can be used for sewn in interfacing and when and where to use them.

RSS Feed

RSS Feed